Annual global resource consumption exceeded 100 billion tonnes in 2017, almost doubling the per capita consumption rate of 50 years ago, and jumping 8% in just 2 years.

Of this figure, the construction industry is responsible for between one-third and 40% and a similarly high proportion of waste, as very few construction components and materials are reused or recycled. Indeed, some construction materials are never used before they are scrapped, research suggests that as much as 20-30% of the materials delivered to construction sites in Brazil are discarded without being used. In the UK, this figure is around 13% and in the Netherlands between 1-10%.

"Some construction materials are never used before they are scrapped, research suggests that as much as 20-30% of the materials delivered to construction sites in Brazil are discarded without being used. In the UK, this figure is around 13% and in the Netherlands between 1-10%."

Material efficiency is at the heart of circular approaches in construction, as well as designing for adaptation, and disassembly and to preserve the value of materials beyond their initial use. A key conceptual shift is to think of buildings not just for their primary purpose, but also as a method of storing thousands of tons of valuable products and materials, which can be traded and reused at the end of the building’s life, rather than just discarded.

This approach is being advocated by the Buildings as Material Banks project (BAMB), which promotes tools such as electronic materials passports and reimagines a building as a dynamic data-tracked repository of tradable value. You can see it in action with companies, such as NetLet and Loopfront, companies that collect unused materials from construction sites, check, processes them and then sell them on. In its first year of operation, NetLet has saved over 1.5 million kilos of surplus building materials.

Case study: netlet

Netlet is a Finnish company that collects unused materials from construction sites, checks, processes them and then sells them on.

In its first year of operation, NetLet has saved over 1.5 million kilos of surplus building materials.

Who is driving the demand for Circular Economy approaches in construction?

In short, almost everyone, at least in northern Europe, where circularity principles can be found to varying degrees in a wide range of green building schemes and regulations. And, although reducing waste can clearly lead to reduced long-term costs, the main motivation for many clients is the growing role of circularity in green building certification requirements and statutory regulation, including France’s HQE Economie Circulaire, the UK’s London Plan Circularity Statement and Italy’s National Green Public Procurement Action Plan. At One Click LCA, we have long promoted resource efficiency as an often-overlooked route to carbon reduction. Our life-cycle assessment (LCA) tools provide information on the percentage of recycled content in materials and products, and enable designers to test material options to identify where savings can be made as well as exploring which end-of-life scenarios will reduce impact. Whilst our Building Circularity Tool enables construction designers to measure and visualize the circularity of a design.

Find out more about the benefits of the Building Circularity tool below.

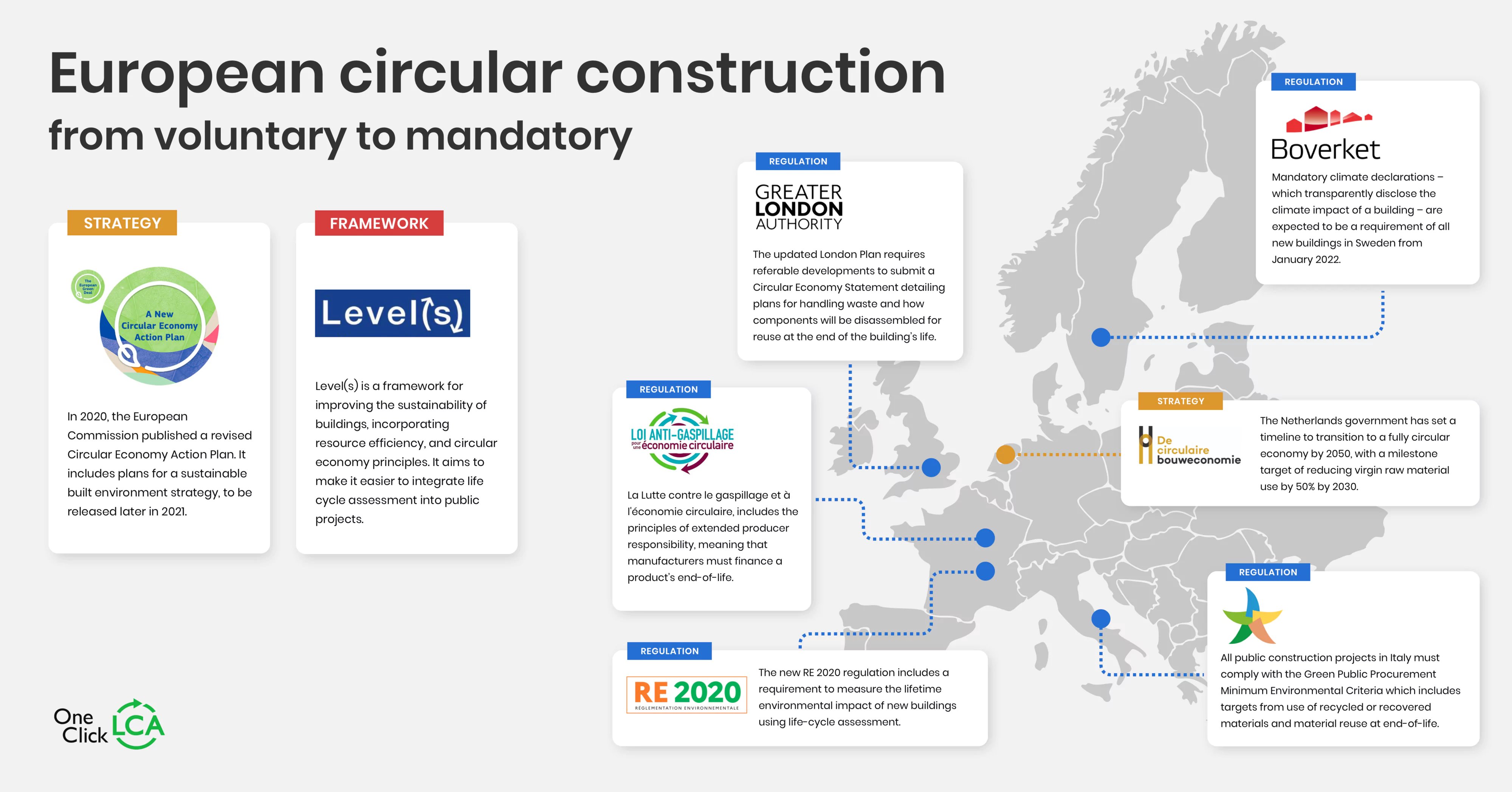

A Snapshot of Circular Construction Initiatives in Europe

Circularity principles can be found to varying degrees in a wide range of green building schemes and regulations in Europe, this is an overview of just some of the initiatives which require circularity indicators to be reported upon.

EU-wide: the EU Circular Economy Action Plan

In March 2020, the European Commission published a revised Circular Economy Action Plan (building on one launched in 2015), which aims to accelerate the changes needed to realise the European Green Deal. It includes plans for a sustainable built environment strategy, to be released later in 2021, which is expected to include measures on recycled content requirements, design for durability and adaptability, integrating LCA into public procurement and potentially revised material recovery targets.

France: HQE, RE 2020 and Waste and Circular Economy Law

A law designed to combat waste and promote a circular economy was adopted in February 2020, La Lutte contre le gaspillage et à l’économie circulaire, will come into force in early 2022. With the French building sector generating 42 million tonnes of waste, a key principle for the construction sector is that manufacturers must finance a product’s end-of-life. A concept referred to as extended producer responsibility or la responsabilité élargie des producteurs (REP) in French. The law aims to improve construction waste management and also to fight against illegal dumping.

UK: the GLA London Plan, the Ellen MacArthur Foundation and the UKGBC

The statement will require applications to demonstrate how materials from deconstruction or remediation works will be reused or recycled, how components will be disassembled for reuse at the end of the building’s life, how waste and recycling will be handled on-site and the amount of waste expected to be generated by the project.

The Ellen MacArthur Foundation was an early champion of circularity and has produced a wealth of research and guidance to accelerate the uptake of the concept, including developing a methodology for Measuring Circularity. The idea has now gained momentum and some have predicted a growth in circular economy initiatives in response to the Covid pandemic.

In 2019, the UKGBC published hands-on advice on how to implement circular principles: Circular economy guidance for construction clients. One Click LCA’s approach to circularity is closely aligned to the UKGBC position.

Italy: Green Public Procurement and Minimum Environmental Criteria

Sweden: Klimatdeklaration av byggnader

The Netherlands: De Circulaire Bouweconomie (CBE) / Circular Construction Economy Transition Agenda

Circular priorities for construction materials

In 2019, One Click LCA developed a model for incorporating circular principles into every stage of construction – from strategy to the building phase – in the Embodied Carbon Policy Framework for Cities report we co-authored with CNCA.

From reviewing whether new construction is needed and instead identifying opportunities for refurbishment or renovation at a strategic planning level, to specifying that unused materials should be returned or recycled at the end of a project, it covers all stages of construction.

There are a number of core considerations to be taken into account at the design stage. One Click LCA’s Building Circularity Tool helps with all of them.

- Materials efficiency: using less to do more

Designs should aim to reduce the overall amount of materials used over the lifetime of your building – taking into consideration if a material choice will result in more replacements of refurbishments, as well as favouring non-virgin and renewable materials over primary and non-renewable resources. Renewable materials are those usually sourced from resources that can be replenished, or regenerated, such as timber from sustainably managed forests. - Ensuring that materials have a life beyond their initial purpose

Design for Disassembly, Design for Adaptation and Value Conservation practices ensure that materials have a life beyond their initial purpose. These approaches require an understanding of the building and its components life-cycle and potential for reuse to ensure that the maximum possible amount of components and materials can be dismantled, recovered and reused once their initial use is over. - Material choice

Some material groups, such as metals will lend themselves more easily to being reused and therefore to higher circularity scores. Our tools allow designers to explore mitigation measures around different material options. For example for materials like concrete that have a low circularity score, you could opt for using recycled concrete.

One Click LCA Building Circularity Tool

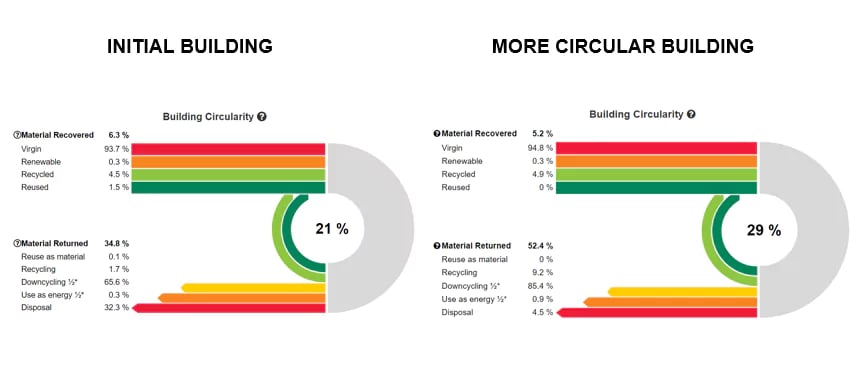

Designers tasked with incorporating circular economy principles into their projects may be newcomers to life-cycle assessment and calculating resource flows. We developed our Building Circularity Tool to make it easier for anyone – regardless of their knowledge of LCA – to measure and visualise the circularity of a design.

One Click LCA Building Circularity Tool

It quantifies resource flows into and out of a construction project, calculating the percentage of non-virgin inputs and non-destructive end-of-life scenarios of your project in order to provide an overall circularity score. You can then make adjustments – for example changing to a recycled material – to see the impact on the overall circularity score.

Alongside the visual overview, the tool also provides a detailed breakdown per material type to support analysis. It also allows you to document where you have incorporated Design for Disassembly and Adaptation practices into your design, for example by choosing dismountable fasteners instead of glue to enable non-destructive removal of the material.

The Building Circularity tool can be combined with any LCA or LCC indicator, including BREEAM and LEED and the UK tool supports Ellen McArthur Foundation Circularity Indicators.

Carbon Experts Newsletter

Industry news & insights — straight to your inbox

Want to learn more?

Asha Ramachandran • Sep 01 2023

Justyna Michalik-Minken • Mar 26 2025

Asha Ramachandran • Feb 08 2024

Asha Ramachandran • Jun 08 2021