How EPDs deliver a competitive advantage for construction product manufacturers

With carbon targets playing an increasingly important role in the construction sector, demand for Environmental Product Declarations or EPDs is growing. In Europe alone, tens of thousands of construction products or materials are now covered by EPDs – and this number is only expected to continue to rise.

However, it is of course the manufacturer who must pay to develop EPDs for their products. And, with average costs of around 15,000 USD, some have questioned whether such an investment is worth it. Here, we look at the clear commercial benefits EPDs can provide to manufacturers, both now and to safeguard your future, as well as how new approaches to developing EPDs can dramatically drive down costs.

EPDs are environmental labels, which provide information on the life-cycle carbon footprint and other impacts of a product or service, based on a life-cycle assessment (LCA). The independent, third-party verified data that EPDs provide is valued across the supply chain, from designers to developers, with many favouring products with EPDs over their competitors without.

EPDs help you meet your clients’ needs

1. Help clients to comply with embodied carbon legislation

Life-cycle carbon limits for new buildings will soon be mandatory in a number of countries, including France, under the new RE 2020 law, Sweden, when the Klimatdeklaration comes into force, Finland as part of its low-carbon construction roadmap, and the UK under the new London Plan. Whole life carbon includes the embodied carbon impacts arising from the extraction, manufacture and transportation of construction materials, as well as the building’s operational energy needs. For your clients – whether developers, designers, specifiers or builders – this means they will need to calculate the lifetime impact of every element of their project, from foundation to facade, via a building life-cycle assessment. As a result, they are likely to prioritise product suppliers who can disclose the environmental footprint of their materials or components via a credible means: enter the EPD. Widely recognised and respected, EPDs are the perfect means to demonstrate regulatory compliance.EPDs versus generic data in building LCA

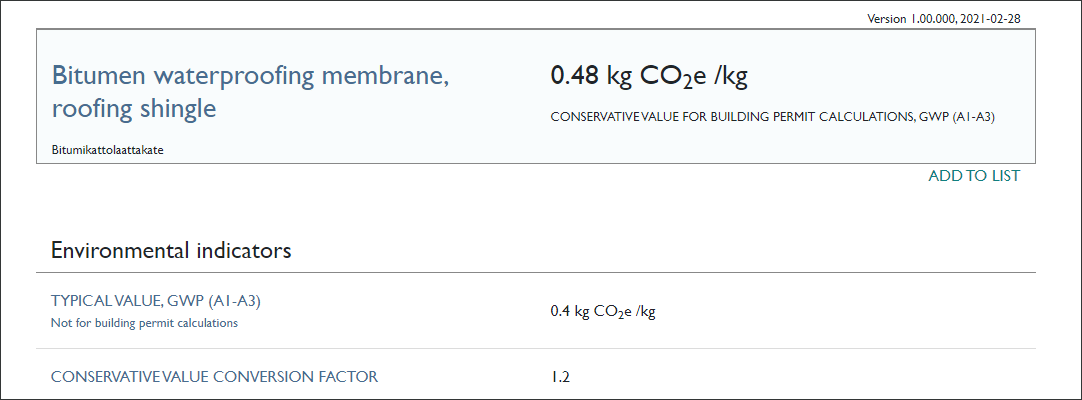

Generic data can be used to perform building life-cycle assessments instead of product-specific EPDs. However, this is not always desirable. For example, the national emissions databases for construction recently launched in Finland and Sweden, use generic data rather than individual EPDs and add approximately one quarter to the Global Warming Potential (GWP) values compared to actual typical product values. Effectively this means that products with data confirmed via an EPD are likely to have lower GWP values than the ‘topped-up’ generic data, and will therefore be more attractive for project owners to use in their building LCA. To understand more about how this works in practice, the screenshot below is from the Finnish emissions database for construction, showing results for bitumen waterproofing membrane for roofing shingle. The typical GWP value for bitumen waterproofing membrane of this type is 0.4 kg CO2e /kg. However, a conservative value conversion factor of 1.2 is applied in the database, meaning that the figure to be included in building permit calculations is higher: 0.48 kg CO2e /kg. As a result, developers may choose to use product-specific EPDs from your competitors in their building LCAs, rather than relying on generic data, to avoid the ‘conversion value’ top-up and achieve a lower overall GWP value for their project.

Data from Finnish national emissions database for construction

EPDs to support carbon reduction targets

Much of the new legislation also includes phased carbon reduction targets. EPDs enable manufacturers to benchmark and then reduce their impacts to ensure that they remain competitive as these limits come into force. It could be that there is no legal requirement to measure or limit embodied carbon in the markets you serve. However, the current steady trickle of forthcoming regulations is expected to expand and, as it does, so will EPD demand. For manufacturers, now is the time to build internal EPD capacity so that you are ready to meet the demand and not lose market share when legislation comes into force in your core markets.

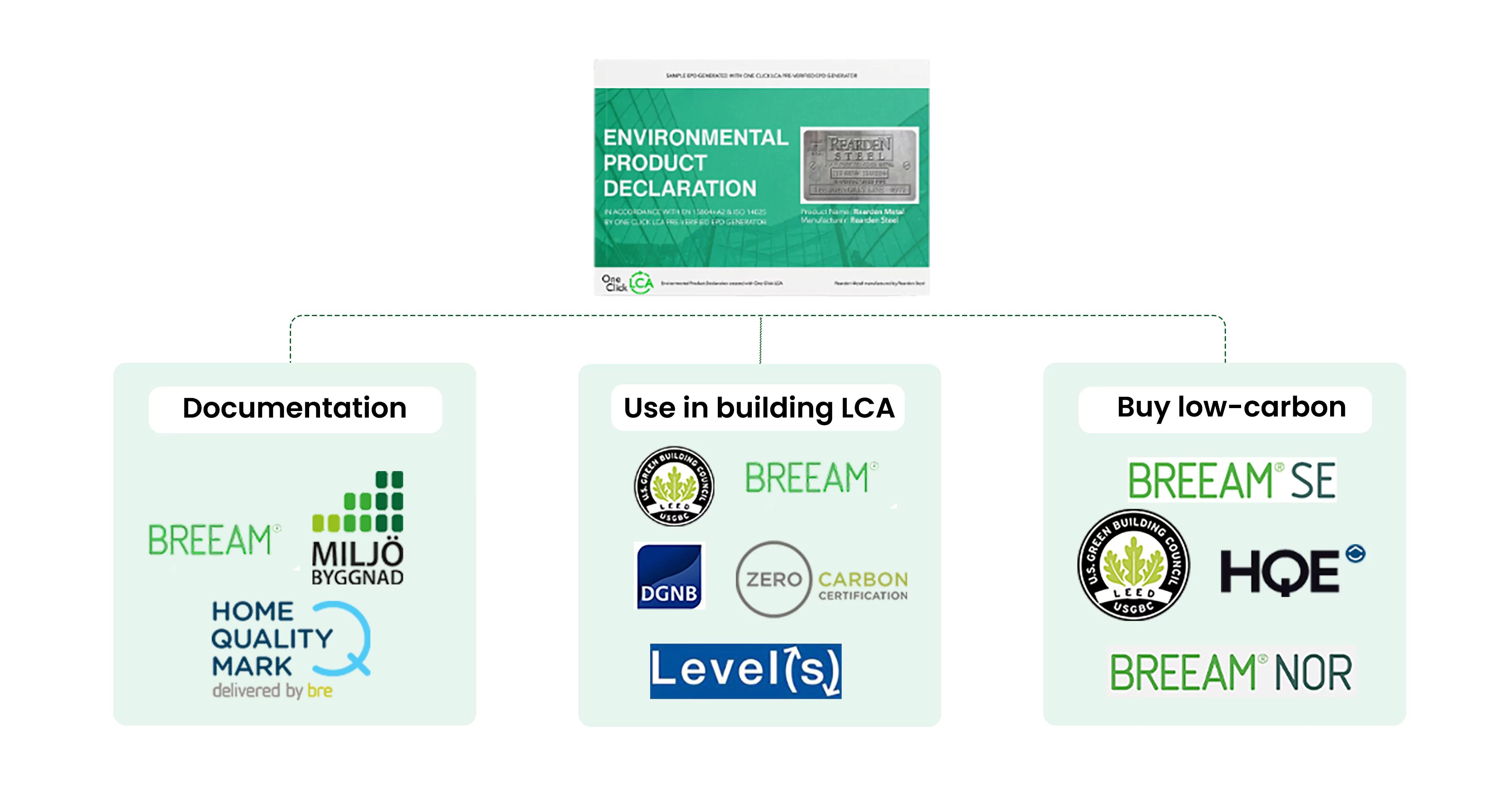

2. Help your clients to gain accreditation for green building certifications and schemes

Around 70 % of international and European green building standards offer credits for the use of construction materials covered by an EPD. So whether your clients need to gain accreditation for LEED, BREEAM, DGNB, the Living Building Challenge or many others, they will prioritise products with EPDs. For many of these schemes, the use of products with EPDs is enough to gain credits, there is no carbon performance target for the products themselves.

EPDs used in green building certifications & standards

EPDs used in green building certifications & standards

3. Help your clients to choose low carbon products

Of the clients who are not working towards a specific certification or need to comply with embodied carbon legislation, many will still be motivated by a desire to be able to choose low carbon products and to demonstrate carbon transparency in their projects. According to recent customer research by Saint-Gobain, 76% of construction product clients want suppliers to be transparent about the environmental impacts of their products. An EPD can facilitate this.

76% of construction product clients want suppliers to be transparent about the environmental impacts of their products.

Source: Saint-Gobain customer research

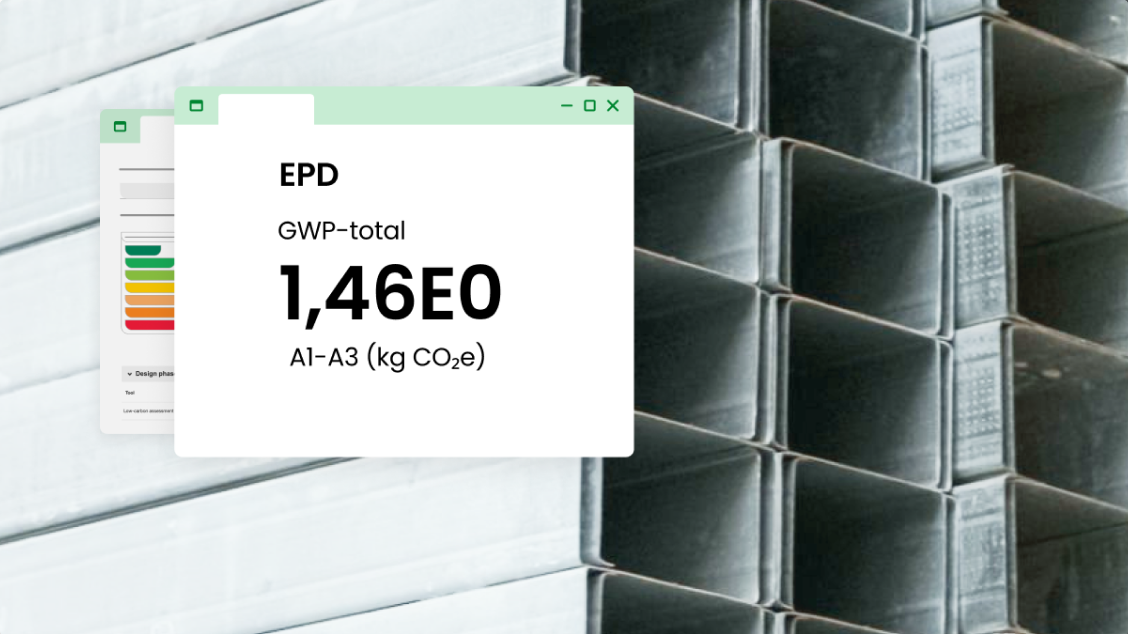

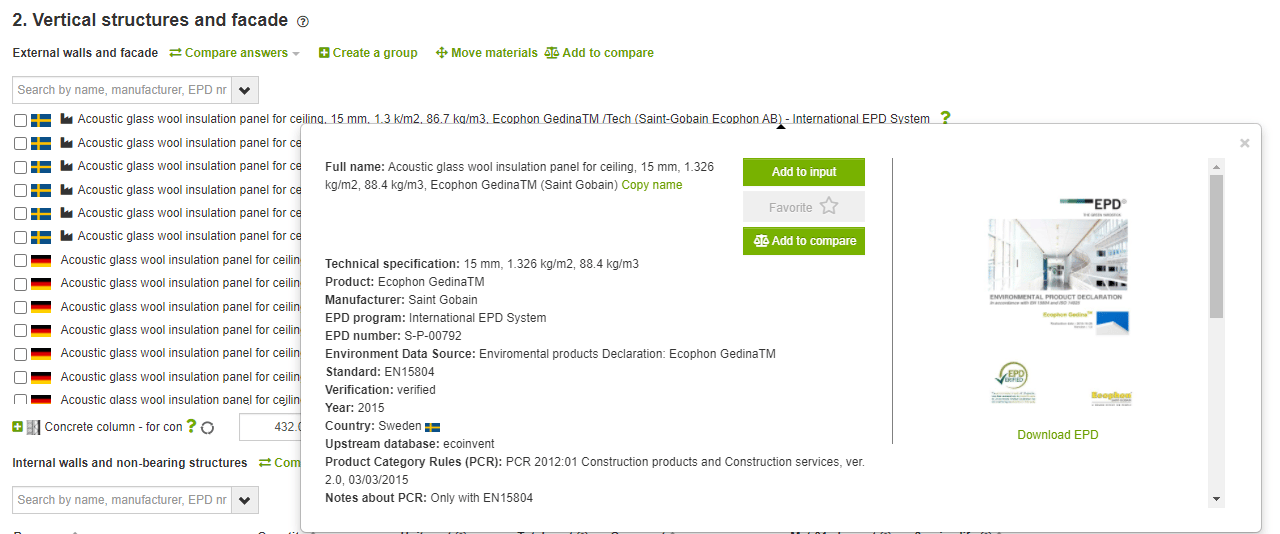

By developing an EPD, you will ensure that your product features in construction sector environmental databases and LCA platforms, such as One Click LCA, so will be seen by clients looking for carbon-transparent products and materials. Without an EPD, you are effectively stepping away from an important ‘shop window’ and making it harder for potential clients to find and choose your product over others on the market.

You need to stand out in a crowded marketplace

4. An EPD demonstrates commitment to sustainability

Investing in an EPD makes it clear to your clients and the wider world that you are not only committed to meeting your clients’ needs – but also committed to sustainability, to measuring and reporting your impact. Once you have your EPD it can play an important role in your marketing, particularly if low-carbon solutions are central to your core offer. For many clients and investors, your carbon footprint or Global Warming Potential (GWP) will be the main information they seek, so should be clearly outlined.

5. An EPD benchmarks your performance

How does your product compare to your competitors in terms of environmental impact? How do your process improvements affect your environmental impact? Without an EPD it can be hard to answer these questions. At the heart of developing an EPD, is the process of measuring your own environmental performance via a product LCA. This allows you to see areas of particularly high or low impact within your own product as well as how you compare to your competitors. Your benchmarking allows you to showcase areas where your product excels and will leave you better prepared to meet growing market demands for product sustainability.

You need to prepare your product for a carbon-focused market

6. Cutting carbon will cut costs

Where there is carbon, there is cost. So identifying and reducing the carbon-heavy aspects of your process could lower production costs, particularly in an industry increasingly exposed to carbon requirements. An LCA allows you to see a comprehensive inventory of all the components and substances used in your product. For many manufacturers, this is the first time such data is gathered in one place. Gathering such data can highlight the choices you have, as well as supporting communication with the rest of your business and supply chain.7. Future-proofing your product development

New rules and requirements are coming into force all the time. By identifying where and how to reduce your impact, you are ready to meet changing sustainability requirements – putting low-carbon and eco-design principles at the heart of future R&D and innovation.The One Click LCA approach: fast, affordable and scalable EPDs

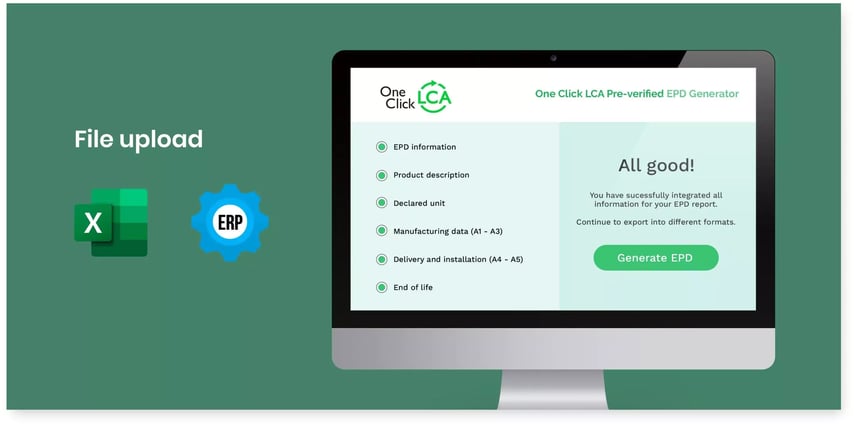

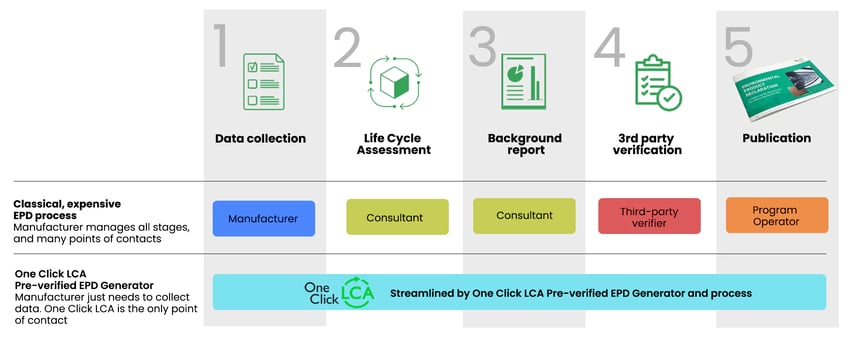

EPDs have the potential to accelerate industry-wide embodied carbon reduction, but to do so we need to reduce the barriers to take up, especially among smaller companies, who may find the initial costs forbidding. At One Click LCA, we are on a mission to do this by driving down the overall costs of creating EPDs and making them achievable for all, without needing to hire specialist LCA expertise. One of the ways we are doing this is via our pre-verified EPD generator, which slashes the cost and time involved in developing an EPD, as we coordinate the third-party verification and publishing side of things. Our platform is designed to be accessible to LCA and EPD newcomers and we also offer hands-on support, you just need to collect your data and answer a few questions and we will guide you through the process. Manufacturers also benefit from the networking aspects of One Click LCA. You can send product data directly to clients and they can request EPDs from you. If your clients are not looking for full third-party verification, you can also use One Click LCA to share LCA data – without the need to pay for verification or publishing. There is also an option to conduct a simplified LCA, looking only at CO2 impact, via a product carbon footprint, which may be all that some clients require.

Six policies driving EPD demand

DENMARK

What? In March 2021, Denmark agreed to introduce carbon calculation requirements for new buildings by 2023, and carbon limit values for buildings over 1000 m2 by 2023 (for all buildings by 2025).

When? Expected by 2023 with the carbon limit values for all buildings due in 2025.

What it means for manufacturers: To support these LCA requirements, manufacturers will need to label the impact of their products clearly using an EPD. The Danish government has published practical guidance on the LCA methodology to be used, available here: baeredygtighedsklasse.dk

FINLAND

FRANCE

SWEDEN

THE NETHERLANDS

UNITED KINGDOM

In view of the impact it could have, the list above would not be complete without a mention of the US Climate Leadership and Environmental Action for our Nation’s (CLEAN) Future Act. An ambitious climate change bill aiming to achieve net-zero emissions by 2050, the CLEAN Future Act was introduced to the United States’ Congress in March 2021.

The proposed legislation includes plans to develop a national EPD database, a labelling system to promote low carbon construction products and embodied carbon thresholds for public construction works.

Whilst its journey through Congress is unlikely to be entirely straightforward, it is probable that significant elements of the CLEAN Future Act will become law before the end of 2021.

Carbon Experts Newsletter

Industry news & insights — straight to your inbox

Want to learn more?

Aileen Carroll • Mar 20 2025

Laura Drury • Mar 24 2025

Aileen Carroll • Feb 07 2025

Justyna Michalik-Minken • Apr 02 2025