Creating low-carbon light fixtures, or luminaires, is crucial to reducing the carbon emissions in buildings. Read how EPDs help lighting manufacturers create sustainable lighting systems.

The construction and manufacturing sectors account for 57% of global carbon emissions. That’s why decarbonizing the built environment is key to keeping the climate stable and reducing global carbon emissions. One effective approach to decarbonizing the built environment is through the use of environmental product declarations (EPDs) for construction products. This article explores the carbon impact of MEP and lighting systems, importance of EPDs, their impact on the lighting industry, and how they can help in producing low-carbon lighting products, lowering the impact of MEP.

Understanding the carbon footprint of MEP & lighting systems

The construction and manufacturing sectors collectively account for 57% of global carbon emissions. Within this, the mechanical, electrical, and plumbing (MEP) systems, including lighting, are significant contributors. MEP systems can account for up to 50% of the embodied carbon in new buildings, making them a critical area to address for decarbonization efforts. Lighting units alone, a component of MEP, account for up to 15% of global electricity consumption and 5% of global greenhouse gas emissions throughout the life cycle of a building.

What is a luminaire?

A luminaire, also commonly known as a light fixture, is an electric unit that provides illumination. It consists of various components, including the lamp, housing, and other electrical parts. The term "luminaire" derives from the Latin word "lumen," meaning light. Given the complexity and diversity of materials involved in luminaires, measuring their environmental impact is essential.

The role of EPDs in lighting

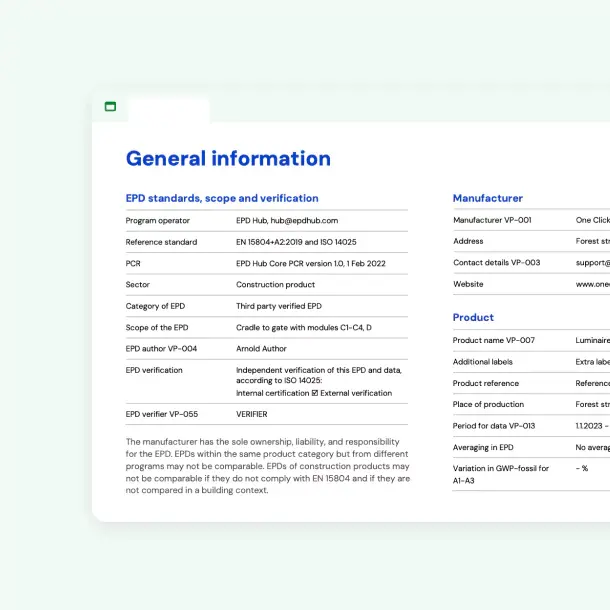

An environmental product declaration (EPD) is a standardized document that transparently communicates the environmental performance or impact of a product throughout its life cycle. EPDs are crucial in the construction industry as they support carbon emission reduction by enabling professionals to compare the impacts of different materials and select the most sustainable options.

For luminaire products, EPDs provide a detailed analysis of the environmental impacts from raw material extraction, manufacturing, transportation, use, and end-of-life disposal. This comprehensive approach ensures that every stage of the product's life cycle is accounted for, allowing for more informed decision-making.

Product life cycle stages

The process of creating an EPD involves several stages, each contributing to the overall environmental impact of the product. These stages include:

- Product stage (A1-A3): This includes raw material supply, transportation to the manufacturing site, and the manufacturing process itself.

- Construction process stage (A4-A5): This involves transportation to the customer's site and installation.

- Use stage (B1-B7): This stage is crucial for luminaires as it includes operational energy use, which is often the most significant contributor to the product's life cycle impact.

- End-of-life stage (C1-C4): This includes deconstruction, transportation to waste processing facilities, recycling, incineration, or landfilling.

Creating EPDs for your luminaire products

Currently, there are over 50 million SKUs (stock keeping units) for MEP products in the European market, but less than 20,000 EPDs for these products. This major discrepancy highlights a need for further product transparency in the sector and EPDs are the most reliable way to bridge this gap.

Looking at product carbon data for a luminaire product throughout all product stages, from A1 to C4, we observe that one of the main contributors to the environmental impact of luminaires is the operational energy use stage (B6). Typically, almost 90% of the total impact of a lighting product comes from this stage. However, the ecodesign principles implemented in the raw material extraction and manufacturing stages can significantly contribute to optimizing energy consumption during the use phase. By creating EPDs, you can see hot spots in your product’s life cycle and improve its performance during the use stage, hence improving its overall environmental performance.

Create EPDs for luminaires — how to decarbonize lighting

Discover how the Luminaires EPD Generator helps lighting manufacturers create low-carbon products by creating environmental product declarations (EPDs).

Benefits of luminaire EPDs

- Decarbonize lighting

By obtaining consistent carbon data for all products and manufacturing sites, manufacturers can create reliable EPD documents. This helps in benchmarking products against competitors and identifying hot spots in the product's carbon footprint. With this information, companies can optimize processes and materials to reduce emissions.

- Win more business

EPDs help manufacturers comply with increasing carbon regulations and gain accreditation and green certification. These credentials differentiate products in the market and can be a decisive factor in securing contracts. By providing transparent and verifiable carbon data, manufacturers meet the growing demand for sustainable products.

Challenges in measuring the impact of luminaires

- Diverse materials: luminaires consist of metals, plastics, glass, and electronic components, each contributing differently to the carbon footprint.

- Supply chain complexity: sourcing materials from various suppliers with different carbon footprints adds complexity.

- Data availability and quality: there are not enough relevant data points available for luminaire products.

- End-of-life management: luminaires typically have long service lives, often 20 to 25 years or more. Predicting the end-of-life scenario for a product that will be disposed of decades from now adds uncertainty.

Key features of One Click LCA’s Luminaire EPD Generator

The Luminaires EPD Generator offers several features that simplify and enhance the EPD creation process:

- Tailor-made template for light fixtures (luminaires): with ready-to-use templates and relevant generic and EPD data

- Integrated EPD publishing and automated verification: integrated verification with EPD Hub and automated verification after the first three EPDs.

- Automated end-of-life scenarios: The tool automates the modeling of end-of-life scenarios, significantly reducing the time and effort required. Users simply select the appropriate end-of-life process for each material.

- Compliance with EN 15804+A2 & relevant standards: By following specific standards, the tool ensures that all EPDs are consistent in quality and transparency.

- Branded EPD documents: users can upload the logo of their organization and create branded documents in their language of preference.

Leveraging the Luminaire EPD Generator to decarbonize lighting products

In the journey towards a more sustainable future, decarbonizing the lighting industry is a critical step. Luminaire EPDs provide a transparent and standardized way to measure and reduce the environmental impact of lighting products. By leveraging tools like the One Click LCA Luminaires EPD Generator, manufacturers can create accurate and reliable EPDs, optimize their products, and meet the growing demand for sustainable solutions.

Software

Luminaire EPD Generator

Manufacturers can streamline EPD creation for lighting fixtures with One Click LCA's automated, verified Luminaire EPD Generator.

Carbon Experts Newsletter

Industry news & insights — straight to your inbox

Want to learn more?

Melina Zacharia • Apr 11 2025

Melina Zacharia • Feb 09 2024

Laura Drury • Sep 16 2024

Melina Zacharia • Apr 16 2024