-1.png?width=1840&name=Global%20EPD%20requirements%20by%20country%20(3)-1.png)

BIM models for all design stages can be used in conjunction with One Click LCA – this article shows you how. The guidance is not specific to any modelling software, as the same approach works across the entire range of modelling software and formats with which One Click LCA integrates.

1. Different types of modelling levels need to pay attention to different things

Most BIM models (except those which are built from fully detailed module libraries) start with a very limited level of detail. Concept or schematic design BIM models cannot be expected to provide the same level of detail as technical design or as-built models.

This guidance aims to help different levels of BIM models to be used with One Click LCA.

BIM models

2. Using different levels of BIM models

The below table summarizes how different levels of models can be used.

| Design stage | Schematic | Developed | Detailed | As built |

| Level of Development | 100 | 200 | 300+ | 500 |

| Quantities | Not available | Approximate | Accurate | Accurate |

| Objects | No specific objects yet | Generic | Specific | Specific |

| Description | Only external shape modelled usually. Spaces not defined. | Space definitions are in place, and size and form approximated. | Model contains 60 % of the data, quantities are accurate. | Model is verified to be accurate. |

| Using the model | Get approximate areas of building envelope and other elements as available (e.g. floor areas). | Arch: get types of constructions & areasStruct: volumes of materials | Get quantities of materials for most solutions, except complex products (doors, windows, etc) | Get quantities and provenance for materials & products |

| Form of data | Undefined walls in m2 | Arch: defined wall types in m2

Struct: defined material types in m3, kg, m2, m2 or pieces |

As before, but sometimes with known suppliers | As before, but with known suppliers |

| Importing the data to One Click LCA | This level of data is best imported in Carbon Designer, which will pick the typical construction automatically. If type of material (e.g. using CLT) is determined, it can be easily chosen. | This level of data is best imported in One Click LCA either as constructions or materials quantities, or a mix thereof | This level of data is best imported in One Click LCA as materials quantities | As before |

| Determining specific LCA datasets in BIM (if desired) | Not relevant. No specific choices apply in this stage in most projects. | Not relevant to link to a vendor, but can be linked to product standards using One Click LCA names or One Click LCA IDs. | Can be linked to specific products using One Click LCA names, One Click LCA IDs or EPD numbers. | As before |

| Undetermined approach | One Click LCA’s concept phase tool, Carbon Designer, will generate the building and assign the most typical construction for each building part automatically. Carbon Designer is parametrized, and can be customized to best match the desired building. If type of material is determined, it can be easily chosen. | One Click LCA’s adaptive recognition algorithm will attempt applying appropriate assembly or material automatically even when it’s not specified. It will consider preferences of the user and the organisation the user belongs to, or then preferences of other users and learn from user behaviour. | As before | As before |

3. Level of development and matching it to LCA data

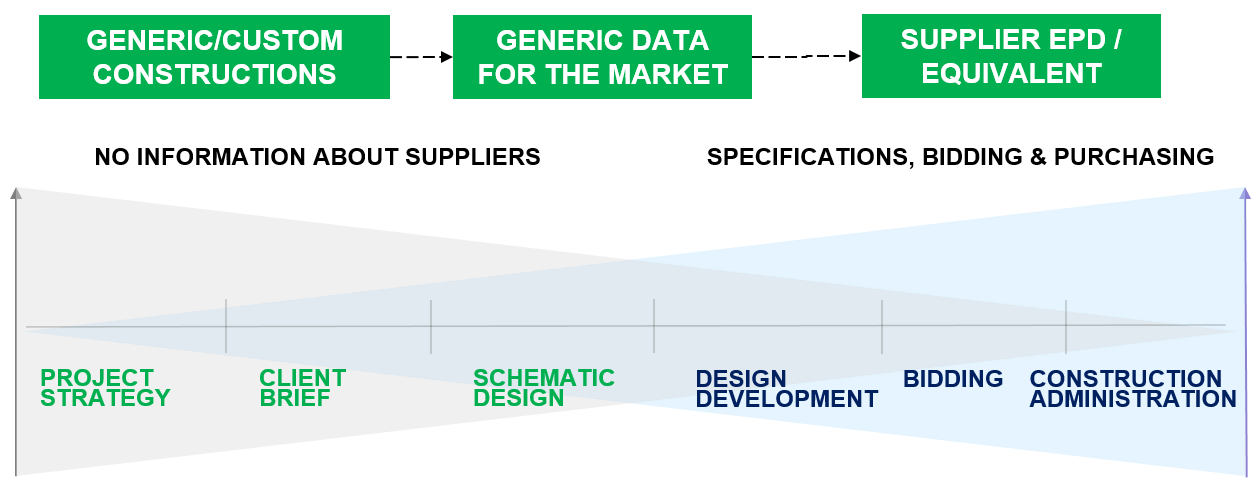

While there are Environmental Product Declarations from several suppliers (some of them shown below), the actual choice of a supplier for a project is typically not done very early on – unless a product influences design in a manner making it necessary to incorporate in the early phase. For example, among the products shown below, only one product, the Deltabeam (Peikko Group) influences the design significantly – in this case, by achieving thinner floor slabs.

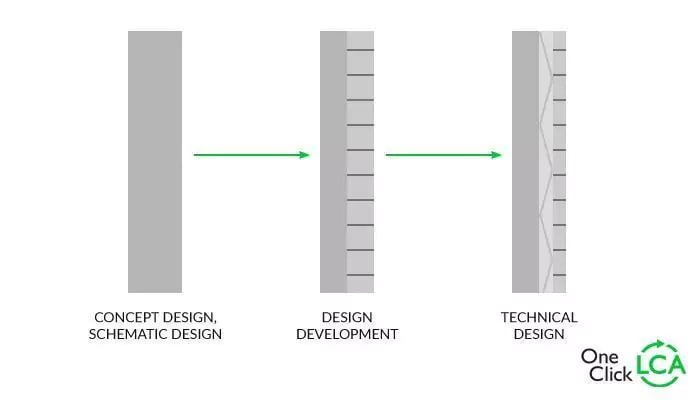

To match the different phases of project development, in One Click LCA, there are several different types of material objects that can be used when a project progresses from early stage to more detailed design. This allows the data to represent the status of the project at any given time.

- Generic constructions. For example, a typical external wall for schools in the UK. This type of data is most appropriate for LOD 100.

- Specific constructions. For example, a brick cladded external wall with U-value 0.17. This type of data is most appropriate for LOD 200 and onwards. Constructions work best up to the point when materials in objects are represented accurately – generally, LOD 300.

- Generic materials. For example, a typical brick such as used in the French market. This type of data is most appropriate for LOD 200 and onwards.

- Manufacturer materials. For example, a brick manufactured by Wienerberger Austria. This type of data is appropriate for any point when sourcing decision is made. That point may be reached sooner, if a contractor has a specific framework supplier for example. Generally, however, this type of data is most appropriate for LOD 300 and onwards.

This is visualized below.

The following section provides a suggested approach to translating these to requirements.

4. Proposed data requirements for BIM models in different stages of design

The below outlines proposed data requirements for models. Any investor or contractor may use these to create their own data requirements for BIM models leveraging One Click LCA.

| Design stage | Schematic | Developed | Detailed | As built |

| Level of Development | 100 | 200 | 300+ | 500 |

| Quantity approach | Areas only | Arch: Areas only

Struct: Volumes |

Volumes, except for complex objects (windows, doors, installations) | Volumes, except for complex objects (windows, doors, installations) |

| Indicative quantity precision | +/- 30 % or more | +/- 15 % | +/- 3-5 % | +/- 0 % |

| Precision requirements | – | Hollow spaces must be modelled | Hollow spaces must be modelled | As before |

| Object coverage | Thermal envelope only | All materials except finishes and installations | All materials except minor fixtures & fittings. | All materials. |

| Object classification precision | – | All objects to be classified in right class/category (no “generic models” or misclassified) | As before | As before |

| Data identification methodology | Labelling | Labelling; or also product standard linking using One Click LCA names or One Click LCA IDs. | Labelling; or even better product linking using One Click LCA names, One Click LCA IDs or EPD numbers. | Labelling and product linking as previously |

Labelling conventions to use and to avoid

The core purpose of the labelling is that it should represent the object from physical reality point of view, to the extent it is known.

Recommended labelling should follow these principles:

- Generally understandable. Clear for all users who need to understand it, for example not using a labelling that can only be interpreted by users in one organization if several need it.

- Physically distinctive. Different from other objects, as relevant to that level of development, when used together with the class or category of the object and other data.

- Physically descriptive. It describes what it is, as relevant to that level of development, or what it consists of.

Some examples of recommended labelling and labelling to avoid are given below. The labels that fall short of the recommended approach but that work as well are given below in the column in the middle. The examples in the column in the middle would either be inherently less precise, or need end user disambiguation.

| LOD | Recommended labelling | These work as well | Labelling to avoid |

| 100 | Brick wall, Envelope, U-value 0,17

Wooden terrace Glass façade |

External wall

Roof, Terrace NB: Carbon Designer defaults work for these |

Colors: grey, white

Phases: phase 1 wall, etc. Internal codes “W0339-a” Generic, Undefined, Draft |

| 200 | Light internal wall, Internal wall, load-bearing

Hollow-core slab Hollow-core slab, C30/37 Glass façade, U-value 0,22 Drywall, acoustic insulation |

Prefabricated slab

C30/37 Glass-alu facade Drywall Timber cladding Window, two pane |

Wall

Default wall Glass Door |

| 300+ | Hollow-core slab, C30/37, L6Drywall, 3 ft stud spacing, metal studs, uninsulated

Metal stairs Steel beam |

Any shown above | Any shown above |

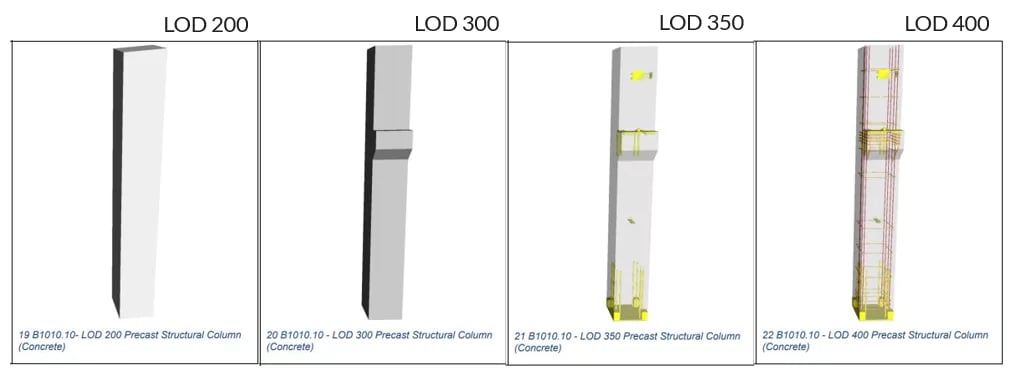

The visualization below shows an example of a precast structural column in different stages of design. In LOD 200 and 300, it could be labelled “Precast column, C40/45”. In LOD 350, the column would be separate object from the connecting parts, which could be labelled “Steel connections”. In LOD 400, the object would contain as separate objects the steel reinforcement tendons labelled “Rebar”.

It is not necessary to label objects based on product environmental data applied. Instead, identifiers can be used (see next section).

5. Connecting objects in models with One Click LCA environmental data profiles – best practice

One Click LCA provides a variety of ways to connect models to environmental impact profiles.

All the data necessary for making the connections is available in One Click LCA data cards. Search for the datasets you wish to use, and copy relevant parameter from the data card. For full name, a “copy name” button is provided and copies the dataset full name to the clipboard automatically

All below provided methods can be used as is for constructions (assemblies) and materials in the very same manner. If a construction (assembly) is used, it will use all its constituent materials.

The different linking methods and their differences are provided below:

- One Click LCA ID. Use field name “OCLID”. This guarantees the same dataset is always used. However, it will not refer to a newer replacing dataset if a new one is issued or this expires.

- EPD number. Use field name “EPDnumber”. This will use the dataset with same EPD number. This is always using the latest issued EPD, if the EPD was reissued because of an error for example. There is a theoretical possibility for a conflict between EPD program numbering systems. This ID can only be used for actual EPDs, not any generic or background data.

- One Click LCA full name. Copy this to the material name field (replace base label). This will always use the latest dataset matching the description. There is a theoretical possibility of a naming conflict where multiple datasets have the same name.

Using any of the above identifiers allows specifying either the material directly, and in case of the first two approaches, without changing the labelling of the objects.

Carbon Experts Newsletter

Industry news & insights — straight to your inbox

Want to learn more?

Aileen Carroll • Mar 12 2024

Aileen Carroll • Feb 26 2025

Ulrika Rudquist • Nov 07 2025

Roberta Belanova • Nov 15 2024