Ireland has a new cement mandate for all state-funded projects. Learn how this policy impacts the Irish cement and construction industries.

Ireland's cement policy signals shift towards sustainable construction practices

Ireland has mandated the use of low-carbon cement for all state-funded construction projects such as roads, schools, and hospitals, starting September 1, 2024. This initiative could serve as a model for other nations working to reduce the environmental impact of the construction industry.

This new policy positions Ireland cement production as a leader in sustainable construction practices. According to the Irish Department of Enterprise, Trade, and Employment, all government or state-funded building projects starting this month must use low-carbon concrete. The rules, which are legally binding, prohibit the use of CEM I, which is a type of cement with the highest emissions.

Ireland's new cement mandate — what it means for construction professionals

The construction sector, particularly cement and concrete production, is a significant contributor to global carbon emissions. Ireland's new policy directly addresses this issue by targeting the 'embodied carbon' in building materials – the emissions associated with their production and transportation.

Key points of the new rule for low-carbon cement (the binding agent of concrete) include:

- Prohibition of high-emission Cem-1 cement in government-funded projects

- Requirement for at least 30% clinker replacement with low-carbon alternatives in concrete

- Application to major state agencies including Transport Infrastructure Ireland and the Health Service Executive (HSE)

What is low-carbon cement?

What is broadly perceived as a low-carbon cement in the construction industry is a concrete mix that results in lower embodied carbon compared to an average mix. Traditional practices to reduce the cement’s embodied carbon include substituting clinker (the key ingredient of cement) with secondary materials from fossil fuel-based processes. Alternative low-carbon cement solutions include:

- Carbon capture technologies

- Carbon dioxide injection

- Biotechnology

- Plant-based solutions

Implications for Ireland's cement ecosystem

By 2030, Ireland cement production is projected to increase, driven by demand for sustainable alternatives. This policy is expected to have far-reaching effects beyond public projects alone. Here's how different stakeholders in the Irish cement industry might be affected:

Cement manufacturers

- Increased demand for low-carbon cement alternatives could drive innovation in production methods

- Potential for new market leaders to emerge based on adaptation speed to sustainable cement

- Possible short-term challenges in meeting new standards for low-carbon concrete

The impact on cement manufacturers is particularly significant, given the scale of cement production in Ireland. Currently, Ireland manufactures approximately five-million tonnes of cement annually, with domestic consumption accounting for about three-million tonnes. Industry projections suggest a substantial growth in production, potentially increasing by 40% by 2030. This growth is expected to be largely driven by demand from government-procured infrastructure projects, underscoring the impact of the new low-carbon cement mandate.

The department's mandate specifically targets a shift away from clinker, requiring that concrete used in public projects replace at least 30% of the clinker content with low-carbon alternatives. This requirement not only pushes manufacturers to adopt more sustainable practices, but also opens up new opportunities for innovation in the cement industry.

Construction companies

- Need for upskilling workforce in handling and using low-carbon cement and concrete

- Compliance with the new guidelines will enable companies to bid for government projects, increasing their opportunities in the public sector

- Potential for cost fluctuations during transition period to low-carbon cement but cost saving in the long-term through improved energy efficiency and reduced waste

- Companies that adapt to these new standards early can become leaders in green construction

Architects and engineers

- Growing demand for expertise in designing with low-carbon cement and concrete

- Architects will need to specify eco-friendly materials that comply with the new regulations, influencing design decisions, especially for concrete-based structures

Ireland cement mandate — global policies on sustainable building materials

While other countries have implemented voluntary guidelines or incentives for low-carbon construction, Ireland's mandatory approach to low-carbon cement sets a new benchmark. This aligns with global efforts to reduce the carbon footprint of the built environment, including:

- The Circular Economy Action Plan is part of the EU's push for circular economy principles in construction, including cement production. This plan includes specific measures for construction and buildings.

- UK Concrete’s Roadmap to Beyond Net Zero is the UK’s cement and concrete industry, represented by the Mineral Products Association (MPA), which launched a roadmap to achieve net-zero emissions by 2050, with an ambition to go beyond net-zero.

- The Netherlands’ Betonakoord (Concrete Agreement) is aimed at making the concrete sector more sustainable by significantly reducing CO2 emissions and promoting circularity in the use of concrete.

Challenges & opportunities for Ireland's cement industry

The transition to low-carbon cement is not without its hurdles. Potential challenges include:

- Initial cost increases as the industry adapts to new cement formulations

- Ensuring consistent quality and performance of new low-carbon cement blends

- Possible resistance from traditional cement manufacturers in Ireland

However, these challenges also present opportunities for Ireland's cement sector:

- Acceleration of research and development in sustainable cement materials

- Creation of new jobs in green technology and sustainable cement production

- Potential for Ireland to become a market leader in low-carbon cement

The role of life-cycle assessment in concrete production

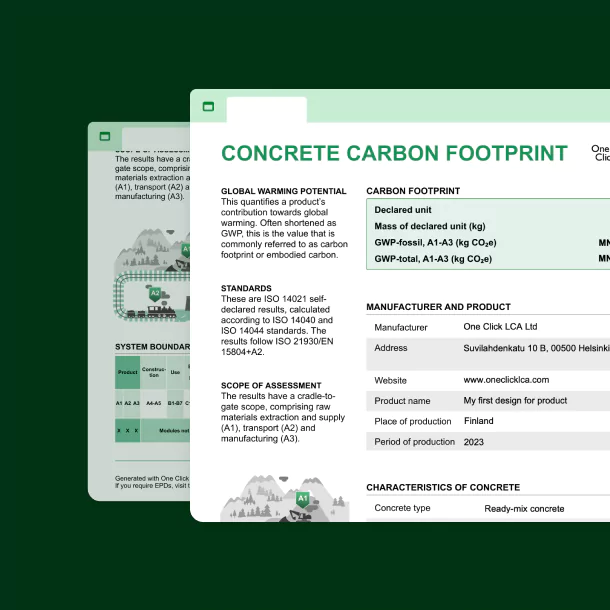

As Ireland's construction industry adapts to these new requirements, accurate measurement of environmental impact becomes crucial. This is where LCA software can play a vital role.

One Click LCA’s comprehensive life-cycle assessment tools such as the Concrete EPD Generator, enable cement manufacturers and construction professionals to:

- Conduct detailed environmental impact analyses of cement and concrete

- Generate environmental product declarations (EPDs) for new low-carbon cement blends

- Compare the performance of different cement types across their entire life cycle

- Optimize material choices for both environmental impact and cost-effectiveness

By leveraging end-to-end sustainability tools, Irish cement stakeholders can ensure they're meeting the new requirements, while also identifying areas for further improvement in sustainable cement production.

The future of Ireland cement production

By taking this step in mandating low-carbon cement, Ireland brings big state infrastructure projects in focus. This marks the importance of state-funded projects to set the pace in driving sustainable construction practices and catalyzing industry-wide adoption of eco-friendly materials.

With this move, Ireland joins the ranks of countries such as the Netherlands, Sweden, Germany, and the United Kingdom in leading low-carbon cement initiatives through green public procurement.

Concrete EPD Generator

EPDs for concrete & cement

The Concrete EPD Generator helps concrete and cement manufacturers to create simplified life-cycle assessments (LCAs) and environmental product declarations (EPDs) for their products fast and at low cost.

Carbon Experts Newsletter

Industry news & insights — straight to your inbox

Want to learn more?

Marios Tsikos • Aug 13 2024

Melina Zacharia • Aug 21 2025

Melina Zacharia • Mar 07 2024

Melina Zacharia • Apr 16 2024