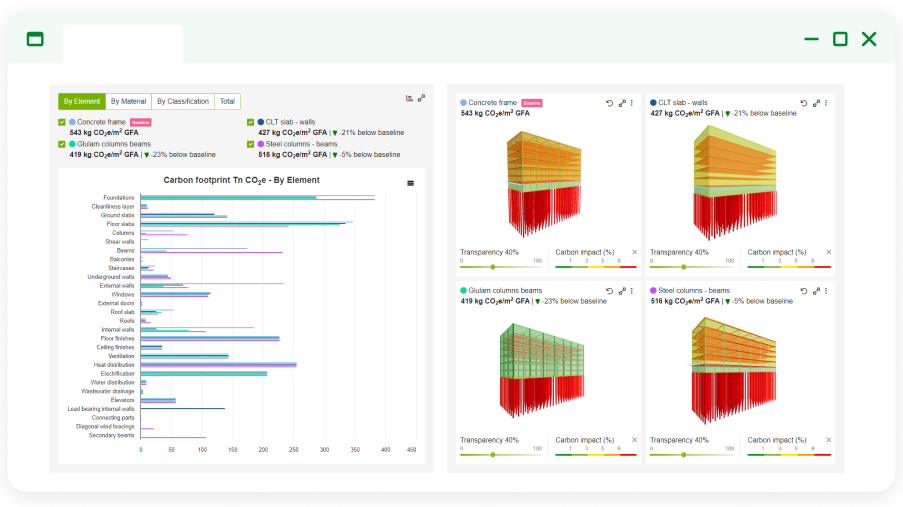

Life-cycle analysis

The evolution of the LCA for the HAUS in 2025

At InstallerSHOW 2025, we released an early A1–A3 LCA for the HAUS. Now, we are sharing the full Whole Life Carbon Assessment (WLCA) — a complete A–D + B6 evaluation aligned with RICS and UKGBC benchmarks.

.jpg)

Summary & interpretation of the A1-A3 LCA report

At InstallerSHOW, HAUS was presented as an 82 m² early-stage concept, and we published a product-stage-only (A1–A3) assessment to understand the carbon profile of the initial bio-based fabric.

What the June study covered

-

Scope: A1–A3 only (no A4–A5, B, C or operational energy)

-

Building size: 82 m² one-dwelling concept

-

Design stage: Conceptual, with several generic/proxy datasets

-

Benchmark: LETI-based A1–A3 benchmark for a typical UK home

Headline June findings

-

474 kgCO₂e/m² product-stage embodied carbon

-

24% lower than LETI’s A1–A3 benchmark for a comparable UK home

-

Hotspots concentrated in the external envelope (74%) and early structural choices

-

Significant biogenic sequestration reported per EN 15804

This study provided an early signal that the bio-based HAUS fabric had potential to deliver strong embodied carbon performance.

WLCA of the HAUS

The new WLCA updates the scope, data quality and design assumptions — producing a complete whole-life carbon evaluation.

What the HAUS WLCA includes

-

Full A–D system boundary, aligned with EN 15978 & RICS 2nd ed.

-

Operational energy (B6) modelled via PHPP (25.83 kWh/m²·yr)

-

60-year reference study period

-

110 m² mid-terrace demonstrator (finalised assembly, services + envelope)

-

43 product-specific EPDs (49.44% coverage) → up from 18 in June

-

Benchmarking against the UKGBC ‘Closing the Gap’ terrace scenarios, with Intermediate–ASHP as the primary comparator

The WLCA is not an update — it’s a complete whole-life cycle evidence base.

Key WLCA findings for the HAUS

Upfront A1–A5:

-

360.74 kgCO₂e/m²

-

~16% lower than UKGBC Intermediate–ASHP

Whole-life embodied A–C:

-

529.07 kgCO₂e/m²

-

~23% lower than UKGBC Intermediate–ASHP

Operational B6 (60 yrs):

-

25.83 kWh/m²·yr

-

~46% lower energy demand than UKGBC Intermediate–ASHP

-

= −34.89 tCO₂e per dwelling over the RSP

Big-picture impact:

Across 100,000 homes, the HAUS design approach would deliver −1,235,730 tCO₂e (A–C) and −3,488,681 tCO₂e (B6) (illustrative, not forecast).

From early insights to whole-life validation for the HAUS

The WLCA report explains the two drivers of change:

1. Specification improvements

-

Bio-based assemblies refined

-

Leaner detailing

-

Clear design choices enabled by the insights from the June study

2. Data quality upgrade

-

The number of EPDs supplied increased from 18 to 43

-

Generic HVAC and electrical datasets replaced with product-specific data

-

Higher-quality envelope and MEP datasets

-

Lower modelling uncertainty

These changes mean the WLCA gives far more reliable, decision-ready results than the earlier assessment.

About the assessor

This report was prepared by Samuel Boswell, Business Development Consultant at One Click LCA and former sustainable architecture professional.

Samuel has been trained in building Life Cycle Assessment by One Click LCA Ltd, an approved training partner of BRE Academy, multiple Green Building Councils, and a provider of GBCI-recognised continuing education.

Design & strategic insights

Beyond compliance and certification, the assessment offers practical guidance for:

-

Material selection

-

Supply chain engagement

-

Early-stage optimisation

These insights can inform ongoing design development, procurement strategies, and regulatory reporting as the project evolves.

Register interest to download the WLCA for the HAUS

Fill in the form to receive the whole-life cycle assessment for the HAUS.

the role of epds in AEC decisions

How EPDs impact material selection in AEC

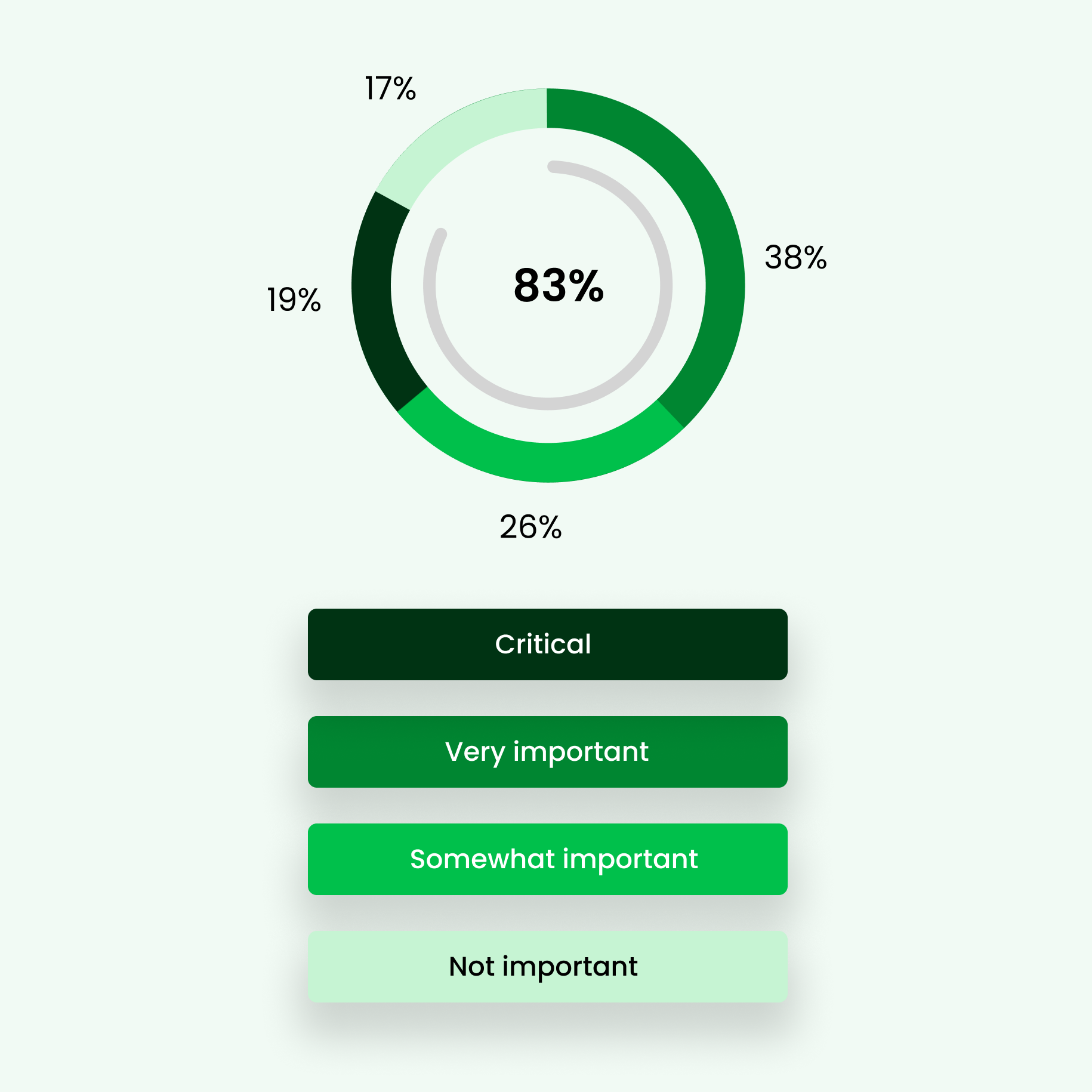

EPDs are becoming a key factor in material selection and procurement, influencing both AEC professionals and manufacturers. Their growing importance is shaping market demand and competitive positioning across regions.

Key insights:

- 83% of AEC respondents report that EPDs influence material selection in building projects.

- 38% consider EPDs very important, while 19% regard them as critical to their decision-making process.

- Only 17% of respondents do not consider EPDs important, indicating that the vast majority recognize their value in material decisions.

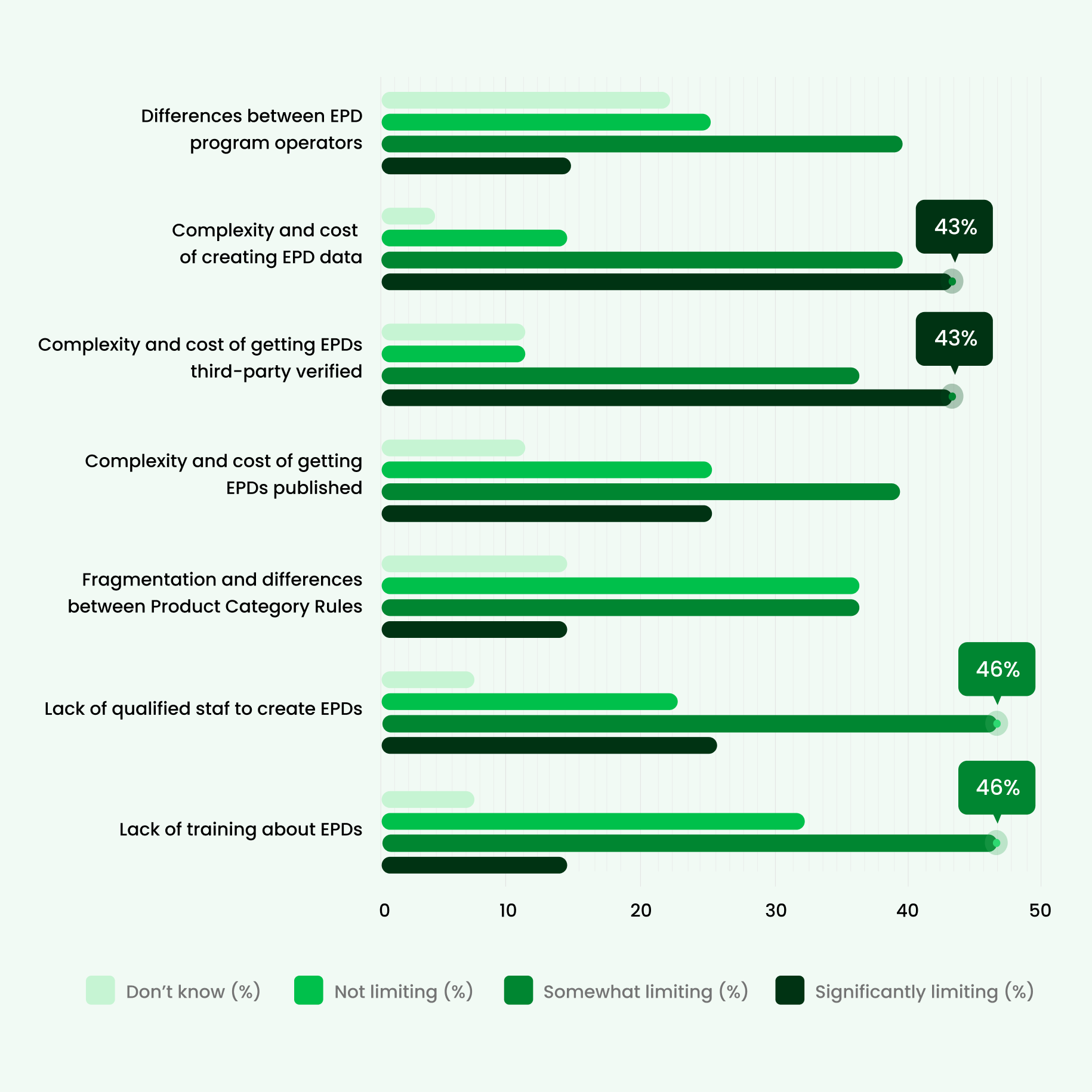

Key challenges for manufacturing

Top barriers to LCA and EPD adoption in product development:

- Over 80% of manufacturers identify the high cost and complexity of EPD creation and verification as the biggest barriers.

- Many manufacturers struggle with the financial burden and technical requirements of producing EPDs, including verification and staff shortages, which limit the number of verified declarations available for material selection.

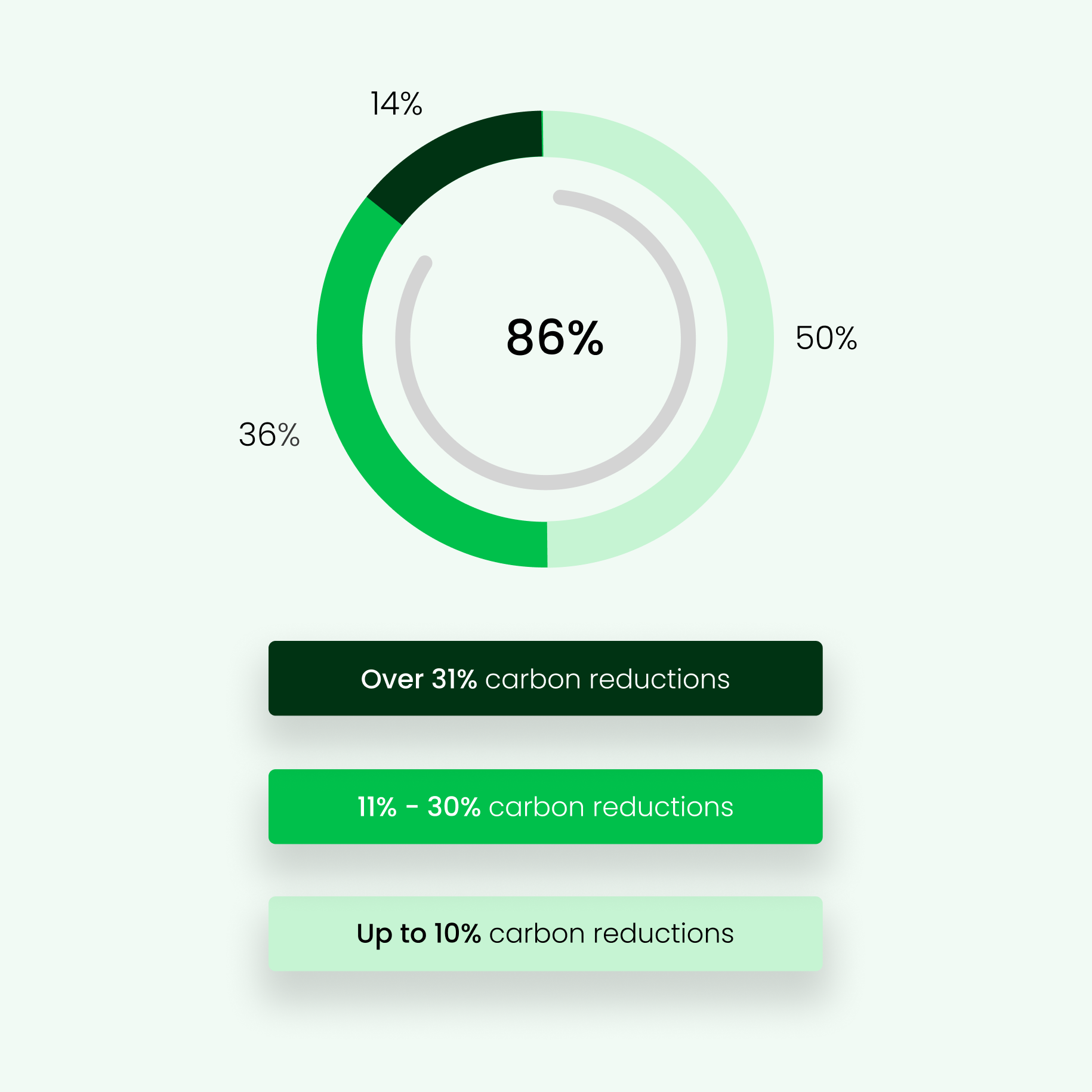

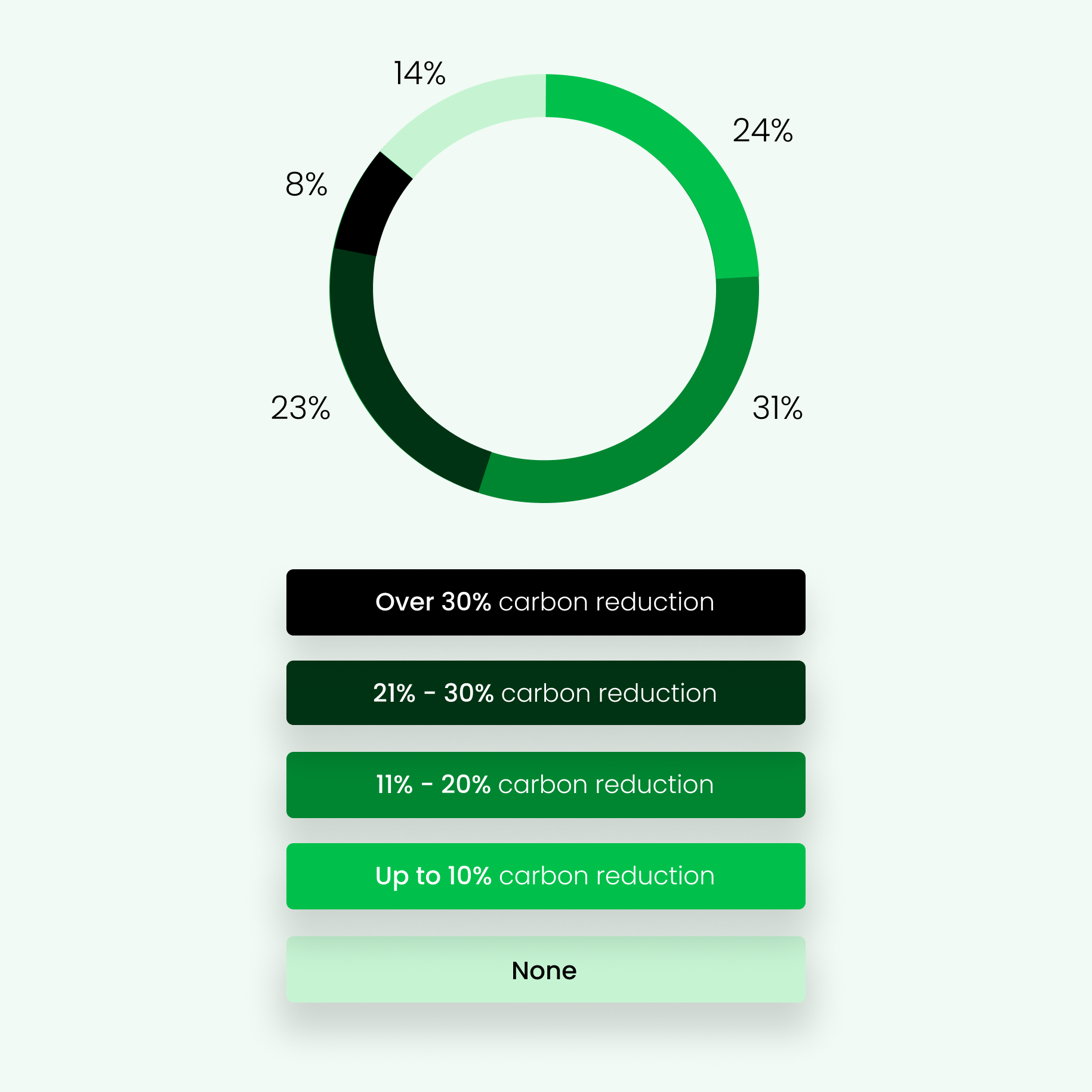

Carbon reduction potential

Carbon reduction potential in manufacturing

The report demonstrates measurable progress in reducing embodied carbon through building LCAs, as well as product LCAs and EPDs, alongside growing confidence among professionals.

Key insights from product development:

- 86% of manufacturers anticipate carbon reductions of up to 30% by applying insights from LCA in their product development processes.

- Within this group of manufacturing experts, 50% expect reductions of up to 10%, while 36% are targeting reductions between 11%–30%.

Download the full carbon report for more insights.

Carbon reduction potential in AEC

The results, based on surveyed AEC professionals, highlight the significant potential of life-cycle assessments (LCAs) to reduce embodied carbon in construction.

Key insights from construction LCAs:

- 31% of AEC respondents report achieving embodied carbon reductions of up to 20% through construction LCAs.

- Over 60% estimate reductions of at least 10% in embodied carbon.

Get the full report for insights into carbon reduction potential across AEC disciplines.

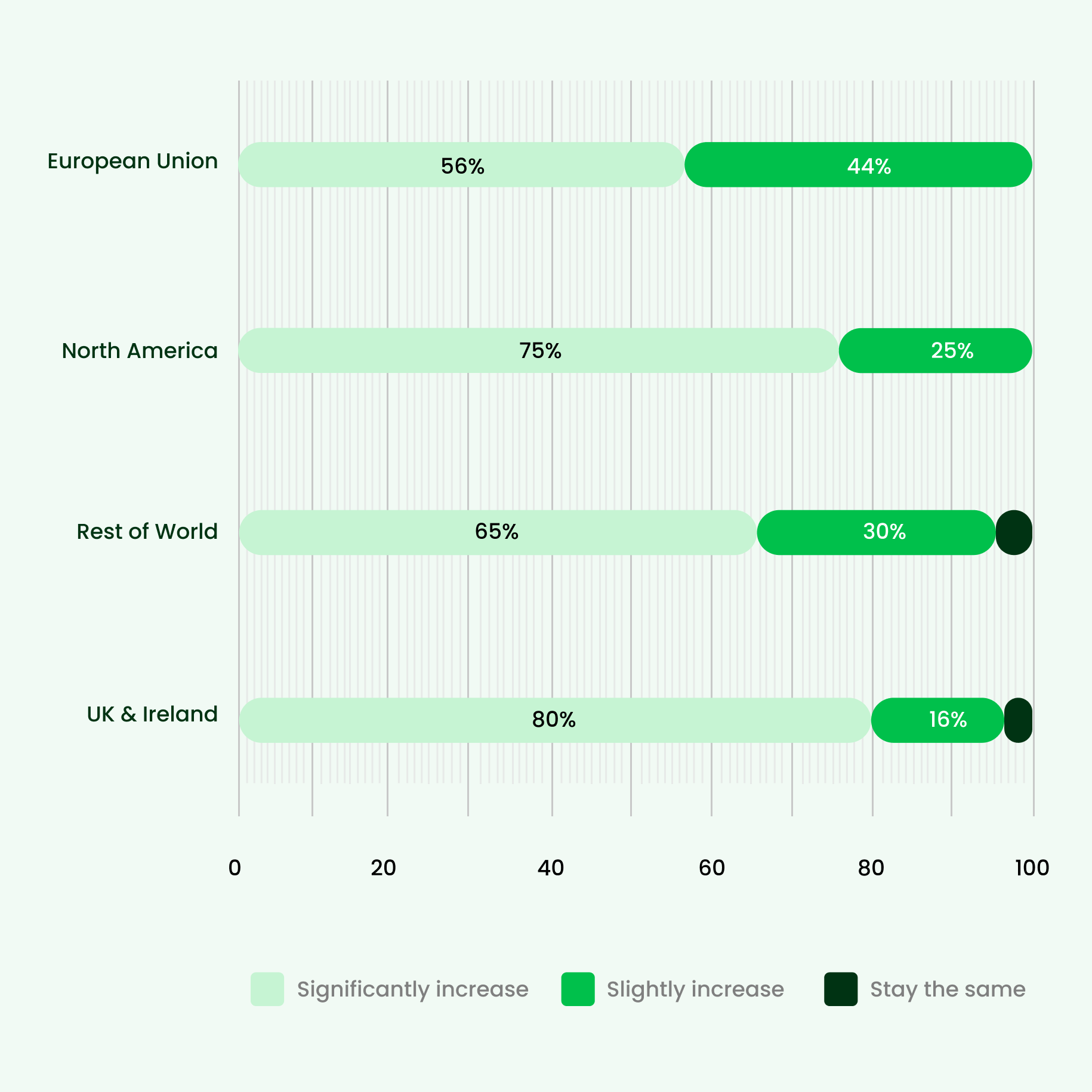

EPD demand to grow ‘significantly’

Both AEC and manufacturing respondents from all surveyed regions anticipate growing demand for EPDs over the next three years. Notably, 100% of respondents in every region expect EPD demand to either increase significantly or slightly.

Key insights:

- 80% of respondents from the United Kingdom and Ireland expect a significant increase in EPD demand within the next three years.

- 75% of North American respondents predict that demand will increase significantly within the next three years.

- 65% of respondents from the Rest of the World expect a significant increase in EPD demand, with an additional 30% anticipating a slight increase.

Download the 2025 report

Get the full report for more insights & data

What you'll find in the full 2025 Carbon Experts Report:

- Detailed regional breakdowns of carbon reduction potential across AEC disciplines and manufacturing sectors.

- Future construction trends, including how automation and digital tools are transforming LCA processes and reducing time and costs.

- Insights into material data gaps in areas like concrete, MEP systems, and steel.

- Regulatory landscape and policy recommendations to support decarbonization at national and regional levels.

- 31 detailed graphs — backed by data from nearly 150 industry experts.

Learnings & opportunities

Insights and opportunities for manufacturers

- EPDs for market growth: With 83% of AEC professionals factoring EPDs into material selection, manufacturers must treat EPDs as strategic assets. Ensuring accessibility, quality, and comparability of EPDs will not only improve procurement success but also enhance competitive positioning. Leveraging automation can scale up EPD creation and reduce costs, making compliance and market entry smoother.

- Adapting to regulations: New regulations such as the EU’s CPR and CBAM are setting higher standards for environmental transparency. Manufacturers who act now — by generating verified EPDs and improving data transparency — can gain early-mover advantages, ensuring compliance while positioning themselves as sustainability leaders.

- Driving industry-wide collaboration: Data fragmentation remains a key barrier, slowing LCA adoption and limiting EPD effectiveness. Collaboration with AEC professionals and suppliers to close data gaps and improve LCA reliability will help overcome this challenge.

Insights and opportunities for AEC professionals

- Maximizing LCA for carbon reduction: Over 60% of AEC respondents report at least a 10% embodied carbon reduction using LCA, with a third achieving up to 20%. Implementing LCAs across all project phases and pushing for lower-carbon materials consistently can unlock even greater reductions.

- EPDs as a core procurement tool: With 83% of AEC professionals considering EPDs critical, prioritizing materials with verified EPDs will drive market shifts toward transparency. Establishing clearer benchmarks and demanding standardized EPDs from suppliers will strengthen material selection frameworks.

- Strengthening manufacturer collaboration: Major data gaps remain in materials like concrete and MEP systems. Working directly with manufacturers to improve data availability and streamline information-sharing will advance reliable environmental assessments and accelerate decarbonization goals.

Connect with an LCA and EDP expert today

Learn more about One Click LCA software and how it can support your projects.