The promise of automated sustainability performance assessment with BIM

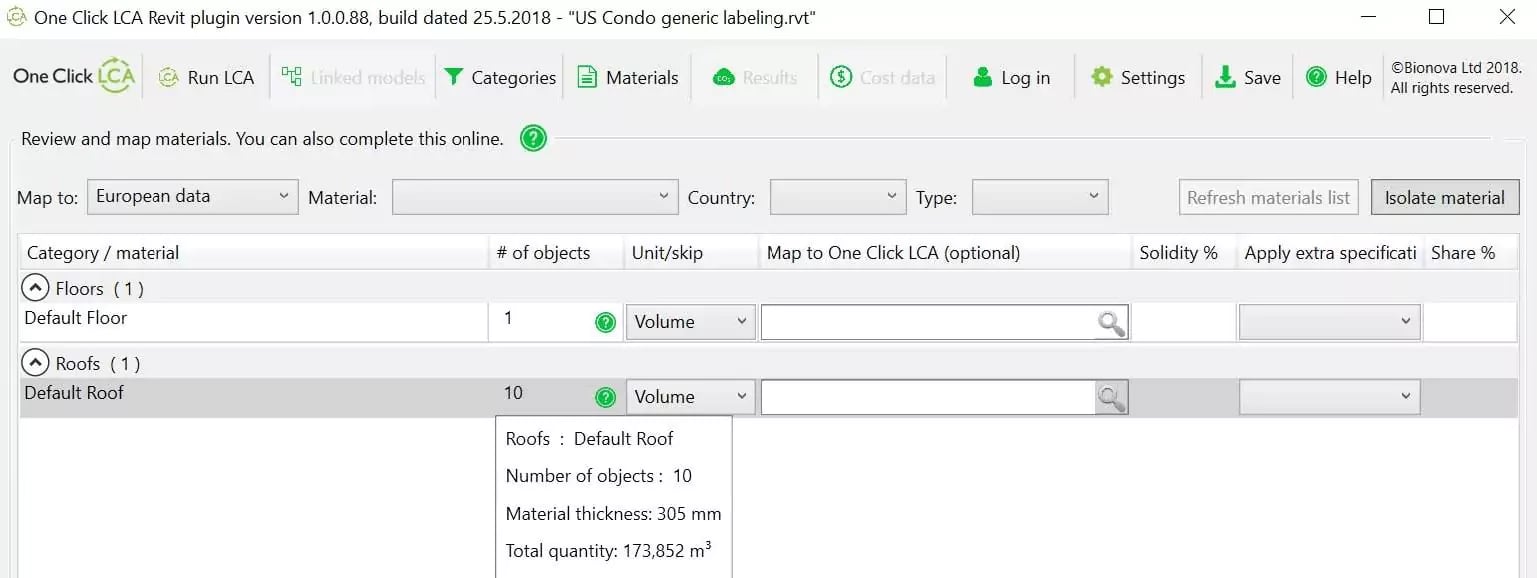

Default Floor and Default Roof – room for improving precision

The premise for automated analysis is sufficient information and accuracy

Ascertaining the building performance needs a minimum level of information, and furthermore, the information must be sufficiently clean, that is – it can not have errors that would render results unsuitable for their purpose. Anyone with experience in working with real-life BIM models created for other purposes than performance assessment knows that many of the models lack some performance-relevant information. When performance assessment is done during the design process to identify optimization opportunities, detail allowing drawing conclusions on studied opportunities is enough. For example, if several external wall solutions are being compared in a life-cycle assessment, say, details of finishings are irrelevant*. Models from different disciplines, for example, between structural, architectural, mechanical and electrical engineering provide different and complementary information on the building. When a project reaches a stage where BIM can be considered as representing the entire building, models from different disciplines are merged into a hybrid model. This model is further refined with information on sequencing and collision analysis to a level suitable for construction drawings and planning. It represents the most accurate pre-construction understanding of the building and can be used for sustainability performance assessment, including LCA and LCC. *In One Click LCA achieved by setting filters to exclude everything except external walls.Life-Cycle Assessment relies on identifying products and materials in the BIM

At the simplest, embodied carbon assessments rely on multiplying quantities of materials used in the building with material environmental impact profiles. This requires assigning each material to a suitable database of environmental impact profiles – and the use of an LCA or carbon database. In case of One Click LCA, which is the software used for this project, the Adaptive Recognition module of the software is able to identify and assign suitable environmental impact profiles for almost all well-defined materials. This still leaves room for some ambiguities that need to be manually defined, or in case of low significance, can also be omitted as explained below. Some of the objects in the model, in particular, smaller systems or parts, for example, lock systems or cabling, are not defined in a way suitable for automated performance analysis. According to European Standards EN 15978, building LCA may omit objects whose total mass is less than 1 % of the building mass, and total omissions may not add up to more than 5 % of the building mass. Applying the standardized cut-off rule would allow omitting such marginal contributors*. In case of commercial certifications, for example, LEED v4, the LCA analysis scope is more narrow and only covers structure and enclosure, making the scope of objects to review and analyze simpler. From this follows that any automated quality assurance of a BIM model for LCA purposes is necessarily context-dependent. * In One Click LCA, a user can choose to filter out marginally contributing items from model automatically.Ensuring BIM quality holds water – Model Checker

- Are materials defined in a way allowing them to be identified (one way or the other)?

- Is model resulting in appropriate precision for the quantities considering the stage of design?

Results of prototyping Model Checker with 50+ real-life BIM models

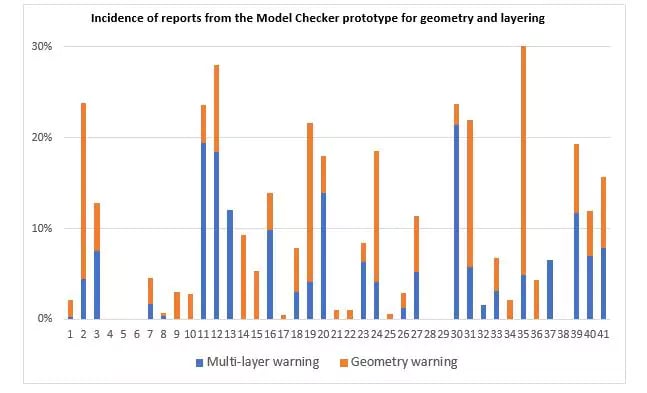

Walls far and wide – many structural models do not define curtain walling and non-load bearing walls

To find out if this works, we created and tested a prototype of the Model Checker with support from the Finnish ministry of environment’s KIRA-digi program. We requested real-life BIM models from various businesses for the test. Our resulting test data set comprised of 61 real-life models from ten different countries. All models were received in IFC2x3 format on “as-is” basis without specific requests being provided other than that models should represent day to day commercial practices and not be of above ordinary quality. When building systems and electrical models were left aside, 41 whole (or substantial part) building models remained for the analysis. Importantly, all models that had been previously analyzed by us were left aside to avoid biasing the sample. This means that the results here should represent what you can expect in a project in your day job. We developed a prototype of Model Checker to test these models and see if errors identified correlated with what our experts could identify in the datasets with desktop analysis. A prototype of the checker was able to report correctly some forms of broken geometry and certain types of problems in multi-layer object definitions. Furthermore, the pre-existing One Click LCA platform itself was able to report unclear labeling issues. The prototype of Model Checker provided a number of relevant errors but turned out to be cumbersome as it triggered also a number of false positives or uncertainties in a way requiring many manual checks (read how we addressed these issues after the prototype). All the prototype checks were run against the entire set of data in the IFC model, irrespective of its materiality for purposes of LCA. This means that the scope of potential errors is far higher than in a case where the model is filtered for the scope that’s actually of interest for LCA purposes.

Rolling out commercially robust Model Checker and LCA Checker in One Click LCA

The prototype version of the Model Checker was rewritten to a commercial grade solution based on the findings. The checker toolkit in One Click LCA now covers two checkers, one Model Checker (for checking the inputs) and one LCA Checker (for checking the quality of resulting LCA). Both interact but work independently. Typically, Model Checker would be used first to review a model received from an architect. Model Checker results can then be used to request the architect to address the issues confirmed as relevant. Only once the results are complete, and also when elements not found in most architectural models, for example, beams and columns, are added, would user run the LCA Checker. LCA Checker, on the other hand, checks the plausibility of the total LCA, irrespectively if data is coming from a BIM, bill of quantities or is inputted by hand by the end user or is a mix of all three. The commercial Model Checker itself was also expanded with scope to address possible classification issues, new types of geometry problems and warnings related to data processing. The LCA Checker, on the other hand, helps users spot clear technical errors in the overall LCA, for example, not having applied enough reinforcement steel to ready-mix concrete, or inadequate fireproofing. Model Checker and LCA Checker are available in One Click LCA Business and Expert level subscriptions.How to deliver a Building Information Model for LCA automation

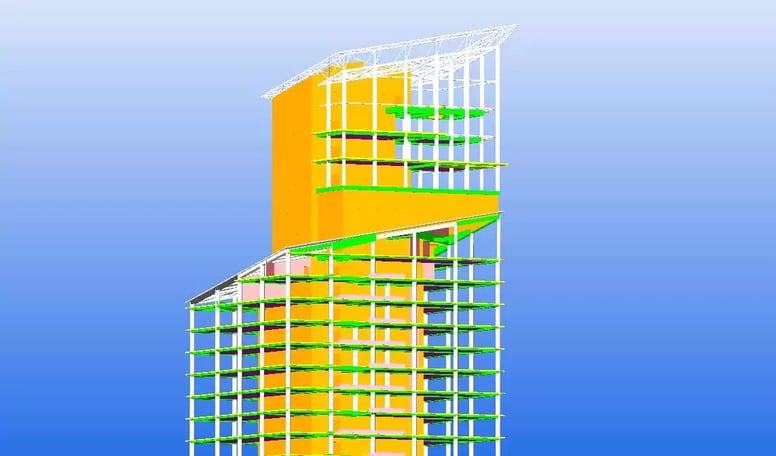

Want to know how to make your BIM model work for Life Cycle Assessment? Read our guidelines on the design principles to follow for BIM models that can easily be used to automate Building Life Cycle Assessment.Some of the BIM models part of the study

Carbon Experts Newsletter

Industry news & insights — straight to your inbox

Want to learn more?

Asha Ramachandran • Feb 07 2024

Marios Tsikos • Mar 21 2024

Panu Pasanen • Dec 01 2021

Asha Ramachandran • Feb 20 2024